Eco-Revolution: PEB Environmental Impact for a Sustainable Future

Nepal’s rapid urban growth demands smarter building methods. Traditional construction, like brick-and-mortar work, creates a lot of waste and uses materials that harm the environment. The PEB environmental impact is different.

These buildings use green materials, save energy, and cut down on waste. They align with global goals, like the United Nations Sustainable Development Goals (SDGs), which push for eco-friendly building practices.

Additionally, a 2019 study in the Journal of Cleaner Production found that modern construction methods, like PEBs, reduce environmental damage by up to 30% compared to traditional methods (Kumar et al., 2019) which makes PEBs a great fit for Nepal’s green goals.

What Are Pre-Engineered Buildings (PEBs)?

PEBs are buildings designed and built in factories before being assembled on-site. They use steel and other recyclable materials, making them strong and eco-friendly. The PEB environmental impact is low because they are made with precision, reducing waste and energy use. Unlike traditional construction, which happens on-site and creates mess, PEBs are clean and efficient.

Key Benefits of PEBs

- Less waste: Factory-made parts mean no extra materials are wasted.

- Energy efficiency: PEBs use insulation and designs that save energy.

- Recyclable materials: Steel used in PEBs can be reused, supporting a circular economy.

- Quick construction: Faster building times mean less energy used on-site.

These benefits make PEBs a top choice for sustainable construction in Nepal.

Read more to discover the Applications of Using PEB in Nepal.

How PEBs Reduce Environmental Impact?

Nepal’s rapid development requires mindful construction methods that align with the UN Sustainable Construction Goals. Traditional methods often generate significant waste, use non-renewable materials, and leave a large carbon footprint.

In contrast, PEB structures utilize recyclable materials, energy-efficient designs, and advanced fabrication techniques, making them ideal for Nepal’s focus on green building solutions.

The PEB environmental impact is positive because it tackles key problems in traditional construction. Let’s break it down.

Reduced Material Wastage

Traditional construction creates a lot of waste. Cutting bricks, mixing concrete, and other on-site work leave behind debris. This harms the environment and raises costs. PEBs, however, are made in factories with exact measurements and every piece fits perfectly, so there’s almost no waste.

A 2020 research paper in Construction and Building Materials found that PEBs can reduce material waste by up to 20% compared to traditional methods (Sharma et al., 2020). This is a big win for Nepal, where reducing construction waste is key to protecting natural resources.

Energy Efficiency: A Step Toward Sustainability

Energy use is a major concern in construction. Traditional buildings often need a lot of energy for heating, cooling, and lighting. PEBs are different. They use insulation, reflective roofs, and smart ventilation to keep energy use low. This reduces the PEB environmental impact over the building’s life.

For example, a 2021 study in Energy and Buildings showed that PEBs with proper insulation can cut energy use by 25–30% compared to traditional buildings (Patel et al., 2021). In Nepal, where energy resources are limited, this makes PEBs a smart choice for businesses and homes.

Earthquake Resistance and Longevity

Nepal faces frequent earthquakes, so buildings must be strong and safe. PEBs are designed to be flexible and withstand seismic shocks. This makes them safer and longer-lasting than many traditional buildings, which can crack or collapse during quakes.

A research found out that PEBs’ lightweight steel frames perform better in earthquakes than heavy concrete structures and this durability means fewer repairs and less environmental damage over time.

Reusability and Circular Economy

PEBs are easy to take apart and move to new locations. This reusability supports a circular economy, where materials are reused instead of thrown away. Traditional buildings are hard to relocate, and demolishing them creates waste. The PEB environmental impact is lower because these buildings can be repurposed.

A research done in Resources, Conservation and Recycling highlighted that PEBs support circular economy principles by using recyclable steel and modular designs. This is perfect for Nepal’s growing industries, which need flexible and sustainable building options.

Moreover, in today’s age, adaptability and reusability are critical for sustainable construction practices.

- Economical and Reusable PEBs: These structures can be dismantled, relocated, and reused, supporting the principles of a circular economy.

- Traditional Buildings: Typically static and inflexible, traditional methods don’t offer the same level of adaptability.

For businesses and industries aiming to grow sustainably, eco-friendly PEB structures are the smart choice.

Lower Carbon Footprint

Construction is a major source of carbon emissions. Traditional methods use heavy machinery, transport materials long distances, and take months to complete. PEBs are faster to build, use less energy, and rely on recyclable materials like steel. This cuts down their carbon footprint.

Research from Environmental Science & Technology (2020) found that PEBs can reduce carbon emissions by up to 35% compared to traditional construction. For Nepal, adopting PEBs means a big step toward cleaner air and a healthier planet.

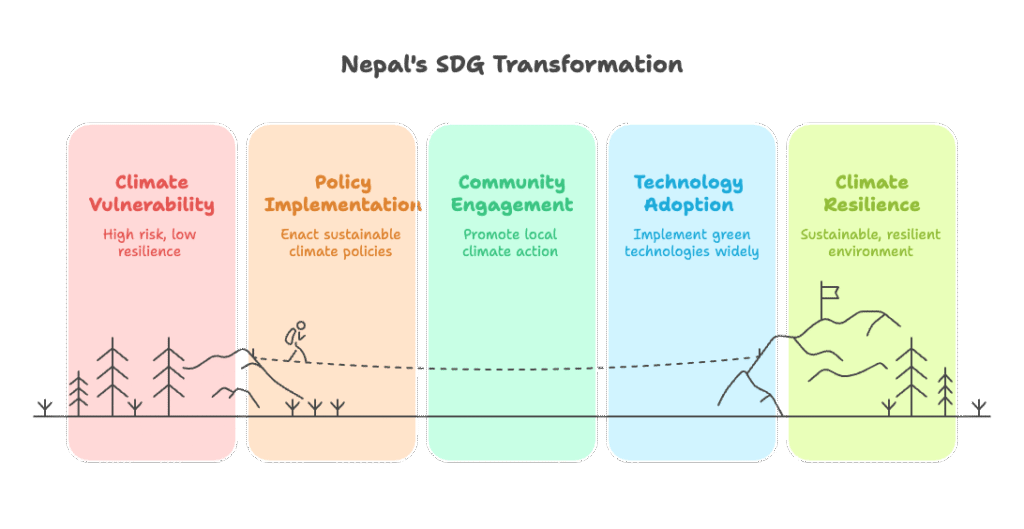

PEBs and Nepal’s Sustainability Goals

Nepal is committed to the UN Sustainable Development Goals, especially those focused on sustainable cities and climate action. The PEB environmental impact helps meet these goals by:

- Reducing waste and pollution.

- Saving energy through smart designs.

- Using materials that can be recycled.

- Supporting safer construction in earthquake-prone areas.

By choosing PEBs, Nepal’s businesses and communities can show their commitment to a greener future. Continue reading: PEB Structures vs. Traditional Construction: Which Is Better for Nepal?

Challenges and Solutions

While PEBs are great, there are challenges. Some builders in Nepal may not know about PEBs or think they are too expensive upfront. But the long-term savings and environmental benefits outweigh the initial costs. Educating contractors and businesses about the PEB environmental impact can help more people adopt this method.

Another challenge is the need for skilled workers to assemble PEBs. Training programs can solve this, ensuring Nepal has the workforce to build these eco-friendly structures.

How to Get Started with PEBs in Nepal

Ready to make your next construction project eco-friendly? Here’s how to start:

- Choose a PEB provider: Look for companies in Nepal that specialize in PEBs, like NSE (National Structure and Engineering).

- Plan your project: Work with engineers to design a PEB that fits your needs.

- Focus on sustainability: Ask for energy-efficient features like insulation and reflective roofs.

- Check for compliance: Ensure your PEB meets Nepal’s building codes and seismic standards.

By choosing PEBs, you’re not just building a structure—you’re building a greener future.

Conclusion

In the debate between traditional construction and modern methods, PEB structures stand out as a beacon of sustainable construction in Nepal. Their eco-friendly materials, energy efficiency, and earthquake-resistant designs make them the ideal choice for industries, commercial spaces, and infrastructure projects.

Ready to make your construction project environmentally responsible? Explore how PEB Nepal can help you build a greener future with innovative, sustainable solutions.