Continuous Sandwich Panels in Nepal: Types, Benefits, and Cost Guide for Modern Construction

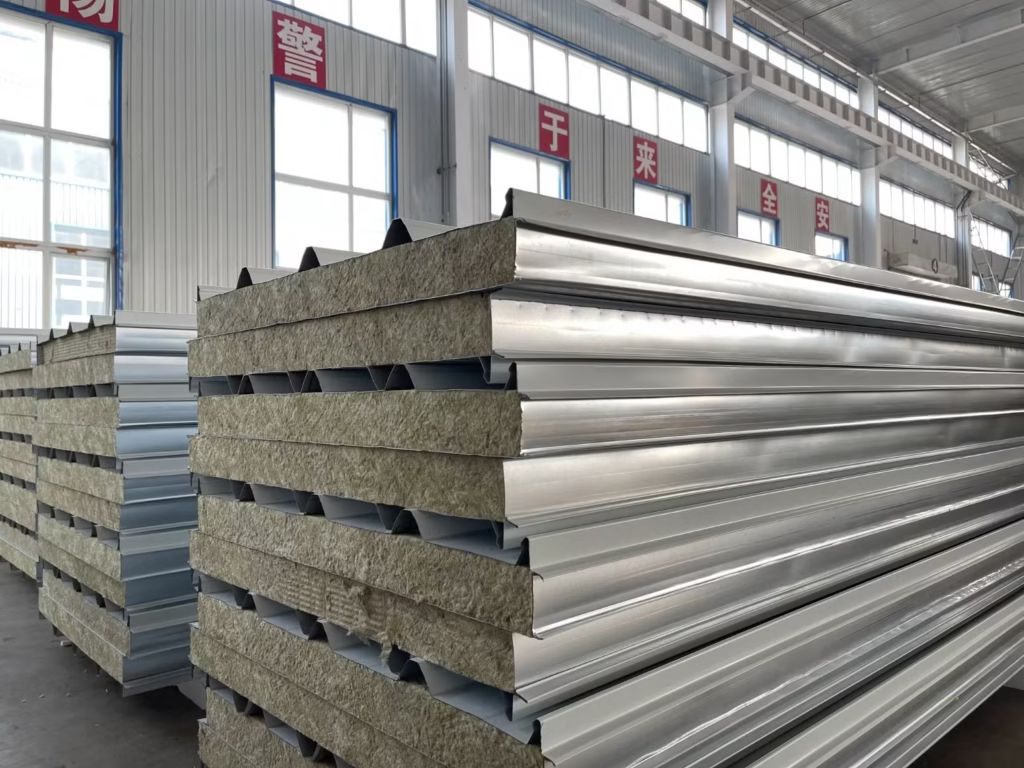

Continuous sandwich panels (CSPs) are a high-performance building envelope solution used widely in industrial, commercial, and residential construction worldwide.

Composed of two facing skins bonded to a lightweight core, CSPs deliver excellent thermal insulation, structural strength, and quick installation.

This article explores types, manufacturing methods, applications, benefits, cost factors, and practical guidance for using continuous sandwich panels in Nepal.

We’ll also answer whether CSPs are applicable in Nepal and provide comparative tables, installation notes, and an FAQ useful for architects, contractors, and developers.

What is a Continuous Sandwich Panel?

A continuous sandwich panel is a prefabricated panel where two outer skins (steel, aluminum, cement board, or fiber-reinforced polymer) sandwich a core material (polyurethane (PUR), polyisocyanurate (PIR), expanded polystyrene (EPS), extruded polystyrene (XPS), mineral wool, or honeycomb).

The term continuous typically refers to the manufacturing and site-installation approach that minimizes joints and provides a continuous thermal and weather barrier across the building envelope.

Key components:

- Outer skins: Usually metal (galvanized or pre-painted steel, aluminum) or cement/fiber boards for fire-rated systems.

- Core: Provides insulation and thickness; choices affect thermal performance, fire rating, and cost.

- Adhesive/bonding: Structural adhesives or continuous lamination processes bond skins to the core.

Types of Continuous Sandwich Panels

1. Metal-Faced CSPs (Steel/Aluminium)

- Core materials: PUR/PIR, EPS, XPS, mineral wool.

- Applications: Warehouses, cold storage, industrial buildings, commercial façades.

- Advantages: High strength-to-weight ratio, easy to fix, aesthetic finishes (pre-painted coils).

2. Cement or Fiber-Reinforced CSPs

- Core materials: Typically mineral wool or PUR/PIR for thermal insulation.

- Applications: Fire-rated walls, schools, hospitals, coastal zones where corrosion resistance is needed.

- Advantages: Improved fire performance and durability.

3. Mineral Wool CSPs

- Core: Mineral wool (rock wool) sandwiched between metal skins.

- Applications: Where fire resistance and acoustic performance are critical.

- Advantages: Non-combustible core, good acoustic absorption.

4. Structural Insulated Panels (SIPs) Variation

- Core materials: Rigid foam cores with stronger outer sheathing (OSB, cement board).

- Applications: Low-rise residential, cold rooms, modular construction.

- Advantages: Structural bearing capacity, fast assembly.

5. Composite and Honeycomb CSPs

- Core: Aluminum honeycomb or composite cores for high stiffness applications (façade elements, floors).

- Advantages: Extreme stiffness-to-weight ratio used in specialized architectural elements.

How Continuous Sandwich Panels Are Manufactured

Typical steps in a continuous manufacturing line:

- Uncoiling outer skins (metal coils or board feed).

- Surface pre-treatment (cleaning, primer, paint if required).

- Core application: Continuous foam spraying (for PUR/PIR) or placing pre-cut core sheets (EPS/XPS/mineral wool).

- Lamination: Skins bonded to the core using rollers under pressure and heat (for continuous lines).

- Cutting/profile finishing: Panels are cut to length and optionally profiled at the edges for tongue-and-groove or clip systems.

Continuous production yields high-quality bonding and a consistent thermal barrier, reducing site labor.

Benefits of Continuous Sandwich Panels

- Thermal efficiency: High R-values per thickness (especially with PIR/PUR cores) reduce heating and cooling loads.

- Speed of construction: Prefab panels allow rapid enclosure of buildings, cutting project schedules.

- Lighter structures: Less dead load compared to masonry or cast systems — useful for retrofit or metal-frame buildings.

- Durability and low maintenance: Metal facings resist weathering; coatings provide corrosion protection.

- Aesthetic flexibility: Wide range of finishes, colors, and profiles.

- Fire and acoustic performance: Choice of core (mineral wool) improves fire resistance and sound insulation.

- Sustainability: Reduced on-site waste, potential for recycled facing materials, and improved building energy performance.

Limitations and Considerations

- Fire performance: Not all cores are fire-resistant. PIR/PUR are combustible unless specially treated mineral wool cores are non-combustible.

- Thermal bridging at fasteners and joints: Requires careful detailing and use of thermal breaks.

- Service integration: Embedding services (conduits, insulation penetrations) requires planning.

- Cost vs. traditional materials: Initial panel cost may be higher than conventional cladding, but lifecycle savings often offset the premium.

- Moisture management: Panels must be detailed to avoid condensation and trapped moisture — especially in cold storage or humid climates.

Are Continuous Sandwich Panels Applicable in Nepal?

Short answer: Yes with specific conditions and proper detailing.

Nepal’s construction needs span diverse climates (tropical plains in the Terai, temperate valleys like Kathmandu, and colder Himalayan regions). CSPs can deliver clear advantages: fast construction for growing urban developments, improved thermal comfort in both cold and hot zones, and durability in rural and peri-urban industrial projects.

Key Nepal-specific points:

- Climatic adaptability: Use PIR/PUR for high thermal resistance where humidity is controlled; mineral wool cores are preferred where fire safety is a priority (public buildings) or in high-temperature zones where fire codes demand non-combustible materials.

- Seismic performance: CSPs are lightweight and, when combined with proper framing, can perform well in seismic zones. Connections and anchorage must comply with seismic design principles consult a structural engineer experienced in lightweight façades.

- Local supply chain: Metal-faced panels and foam cores are available in Nepal through importers and local fabricators who work with pre-painted steel coils. However, full continuous production lines are rare; many local manufacturers supply cut-to-size sandwich panels assembled in shop rather than long continuous lines. This is generally suitable but may impact finish continuity and joint detailing.

- Codes and approvals: Nepal’s building codes and municipal regulations may have specific fire and energy requirements always check local authority requirements and obtain approvals. For health, education, and high-occupancy buildings, expect stricter fire and acoustic standards.

Cost Guide — What Affects Price

Prices vary widely based on core type, facing material, thickness, finish, and economies of scale. Below is a typical cost breakdown and a sample estimate for Nepal (indicative ranges only). Prices are influenced by import duties, local fabrication, transportation, and installation labor.

Cost components

- Material costs: Core (PIR/PUR/EPS/mineral wool), metal facings (pre-painted galvanized steel or aluminum), adhesives.

- Fabrication: Cutting, edge profiling, flashings, and finishes.

- Transport & handling: Panels are large — road transport and careful handling increase costs.

- Installation: Skilled labor for sealing, fixing, and weatherproofing.

- Accessories: Fasteners, clips, seals, thermal breaks, flashings, trims.

Indicative price table (per square meter)

| Panel Type (face/core) | Typical Thickness (mm) | Approx Cost Range (NPR/m²) | Notes |

|---|---|---|---|

| Steel-faced / PIR | 50–100 | NPR 2,500 – 5,500 | High thermal R-value; good for offices/warehouses |

| Steel-faced / EPS | 50–100 | NPR 1,800 – 3,200 | Lower cost, lower R-value; used for non-critical insulation |

| Steel-faced / Mineral wool | 60–120 | NPR 3,200 – 6,000 | Fire-rated; good acoustic performance |

| Cement board-faced / Mineral wool | 60–120 | NPR 3,800 – 7,000 | Durable, used for fire-critical buildings |

| Aluminum-faced / PIR | 50–100 | NPR 3,200 – 6,500 | Lightweight, corrosion-resistant |

Note: These are indicative ranges for planning only. Actual quotes from local suppliers/fabricators are essential. Costs can change with currency fluctuations, import tariffs, and fuel prices.

Example cost calculation (approximate)

For a 500 m² warehouse wall using steel-faced PIR (75 mm):

- Panel material cost (avg NPR 3,500/m²): 500 × 3,500 = NPR 1,750,000

- Fabrication & accessories (est. 15%): NPR 262,500

- Transport & installation (est. 20%): NPR 350,000

- Estimated total: NPR 2,362,500 (approx.)

This example is illustrative, request itemized quotations from at least 3 suppliers and include VAT, transport, scaffolding, and finishing.

Installation & Detailing Tips for Nepal

- Sealing & joints: Use tongue-and-groove profiles or concealed clip systems with continuous gaskets to minimize water ingress.

- Thermal breaks: Install thermal break strips at fixing points to reduce thermal bridging.

- Flashing: Properly flash around openings and roof-wall intersections, Nepal’s monsoon requires robust drainage detailing.

- Condensation control: In humid/wet climates, include vapor barriers and design for ventilation to avoid trapped moisture.

- Fire stops: For buildings requiring fire-rating, use mineral wool cores and certified fire-stopping systems at penetrations and joints.

- Seismic anchorage: Ensure fasteners and substrate framing meet seismic design loads; consider flexible fixings that can accommodate movement.

- Local labor training: Provide on-site training or use experienced installers, careful handling avoids damage to painted finishes.

Sustainability Considerations

- Embodied energy: Metal facings and petrochemical-based cores have embodied carbon; choose panels with recycled content where possible.

- Thermal performance: Better insulation reduces operational energy use a major lifecycle benefit.

- End-of-life: Plan for recyclability — steel facings are recyclable, but separation of core and facings can be a challenge.

Comparative Table: CSP vs Traditional Systems

| Criterion | Continuous Sandwich Panels | Brick/Block + Plaster | Precast Concrete Panels |

|---|---|---|---|

| Construction speed | Fast (prefab) | Slow | Moderate-fast |

| Thermal performance | High (thin profile) | Moderate-low (thick wall) | Variable |

| Weight | Low | High | High |

| Fire performance | Depends on core | Good with masonry | Good |

| Cost (initial) | Moderate to high | Low to moderate | High |

| Maintenance | Low | Moderate | Low |

Use Cases in Nepal — Where CSPs Make Sense

- Industrial sheds and warehouses — speed and insulation.

- Cold storage and food processing — tight thermal control (use PUR/PIR with good seals).

- Commercial façades and retail — fast, attractive finishes.

- Temporary housing & modular schools — quick assembly in disaster relief scenarios.

- Low-rise residential or hostel blocks — where lightweight, insulated panels speed delivery.

Procurement Checklist for Nepali Buyers

- Get thermal (R-value) certificates from suppliers.

- Ask for fire test reports (for mineral wool vs PIR/PUR) and compliance certificates.

- Request samples of pre-painted finishes and edge treatments.

- Confirm warranty on coatings and panel bonding.

- Check anchor/fixation details and seismic design compliance.

- Ask for references of recent local projects.

Frequently Asked Questions

1. Are sandwich panels suitable for Kathmandu’s climate?

Yes, they provide excellent thermal insulation which is beneficial in Kathmandu’s temperate valley climate. Design for ventilation and condensation control, especially during monsoon months.

2. Which core is best for fire safety?

Mineral wool cores are non-combustible. PIR/PUR can be made to meet specific fire ratings but often require additional treatments or fire-stopping details.

3. Can sandwich panels be used for load-bearing walls?

Some SIP-style sandwich panels provide limited structural capacity, but for heavy structural loads, combine panels with a designed frame system and follow a structural engineer’s guidance.

Conclusion

Continuous sandwich panels are a compelling option for Nepal’s evolving building market. They deliver fast construction, superior thermal performance, and design flexibility. However, success depends on choosing the right core for fire and thermal needs, careful detailing for monsoon/condensation control, and ensuring seismic-compliant anchorage.

For Nepali projects, balance cost, fire safety, and local fabrication capabilities. Engage experienced suppliers, request test certificates, and involve structural and MEP consultants early to realize the full benefits of CSPs.

Read More: Pre-Engineered Buildings vs. Prefabricated Structures: A Structural and Cost Analysis